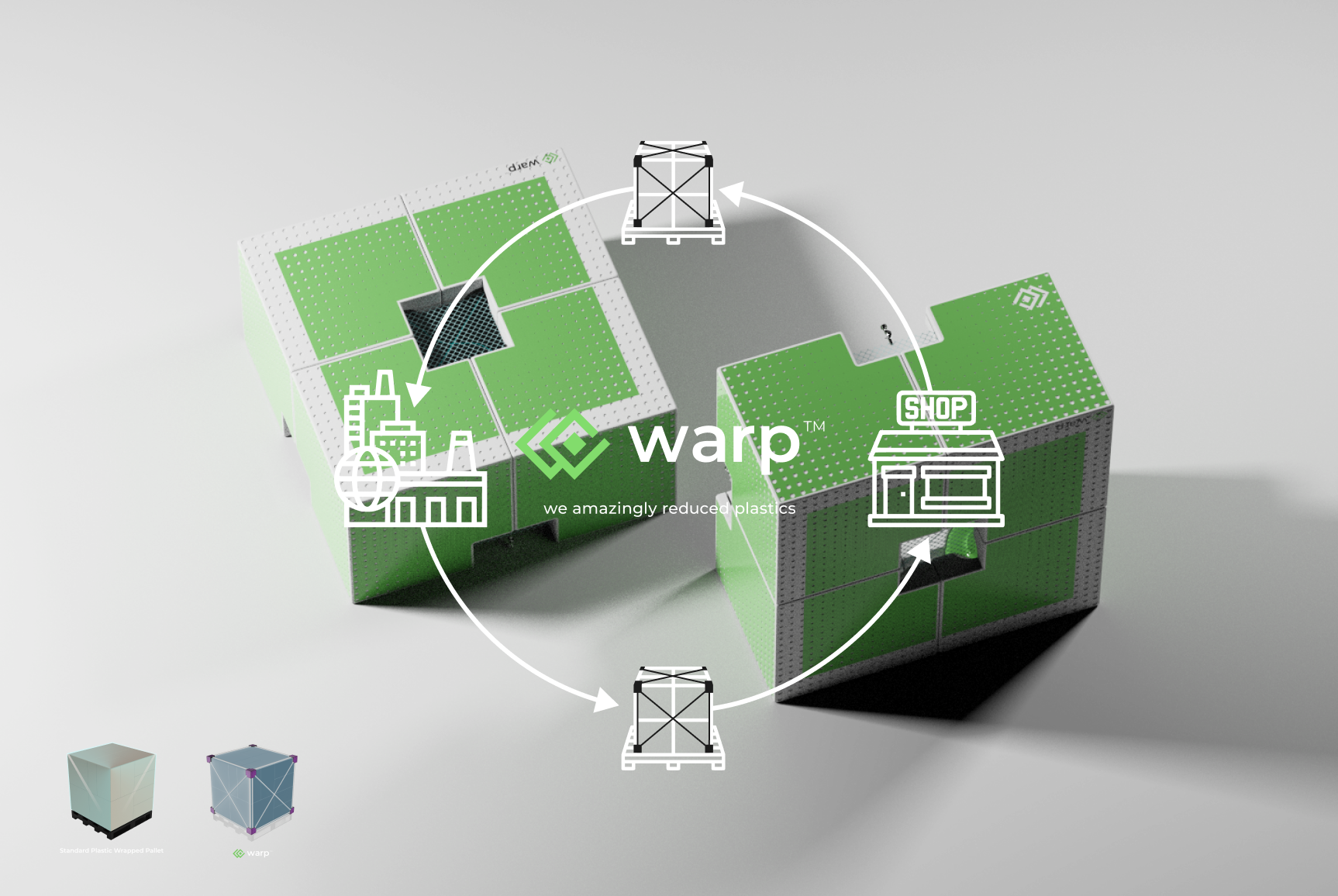

solution

Warp

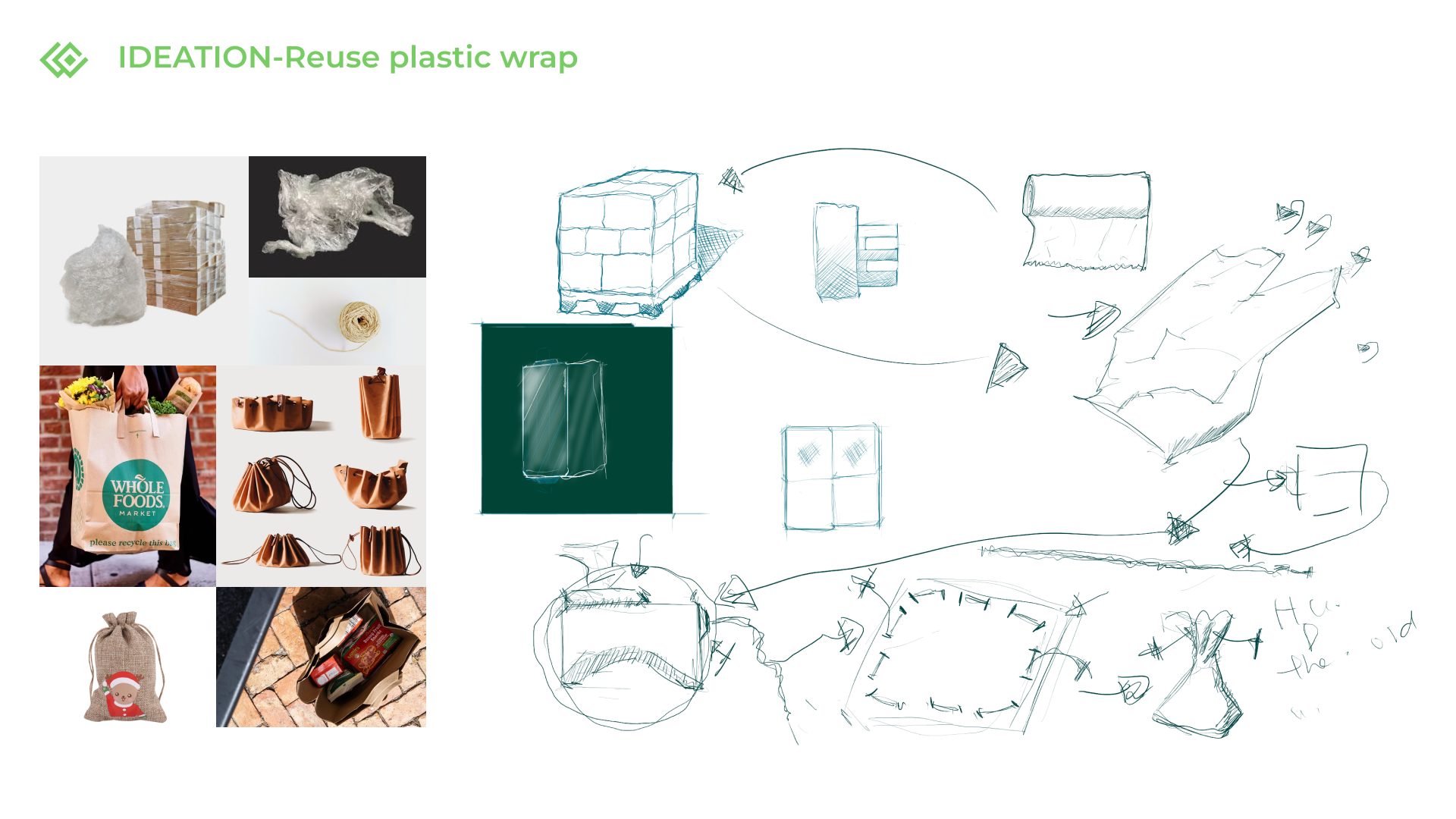

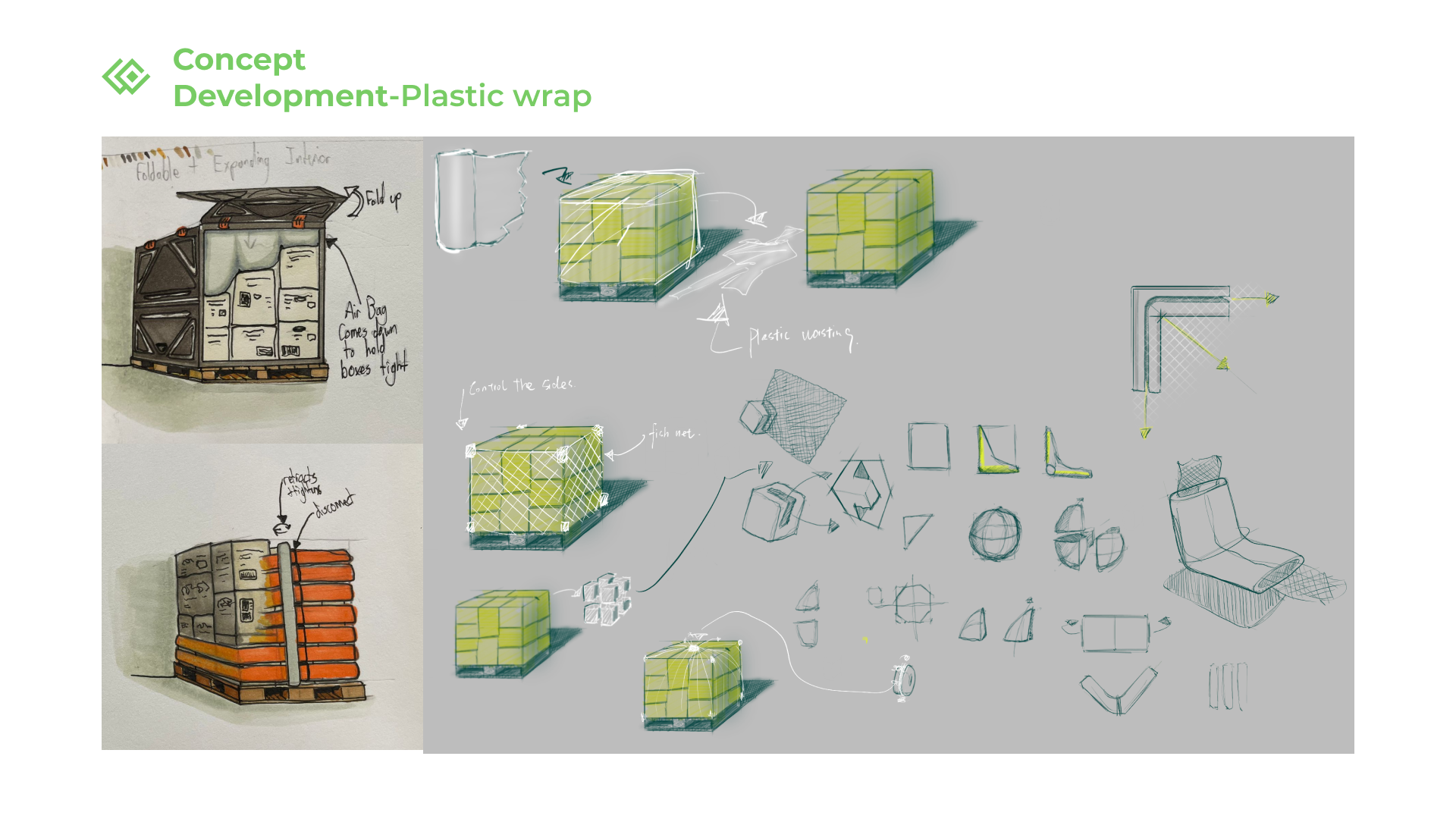

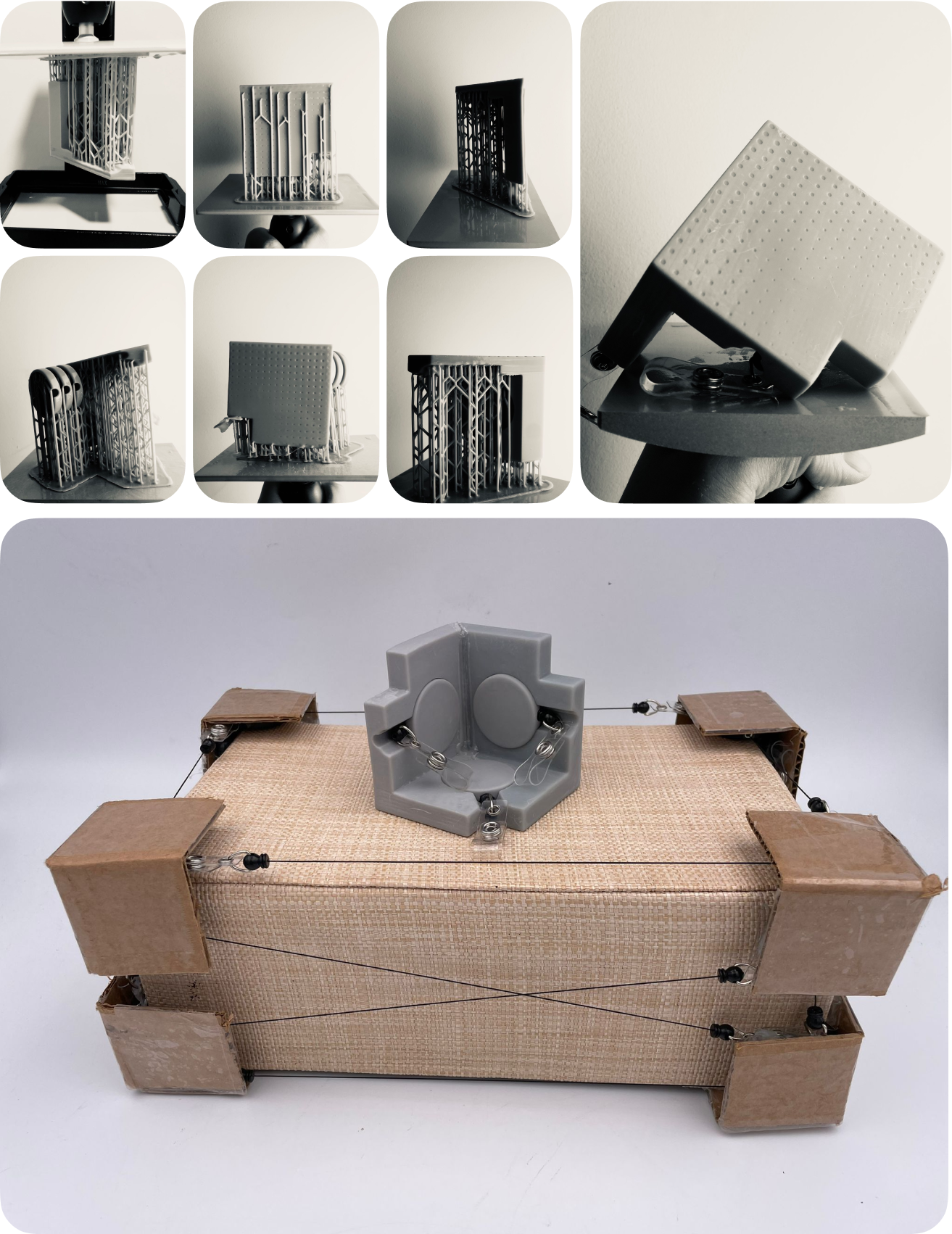

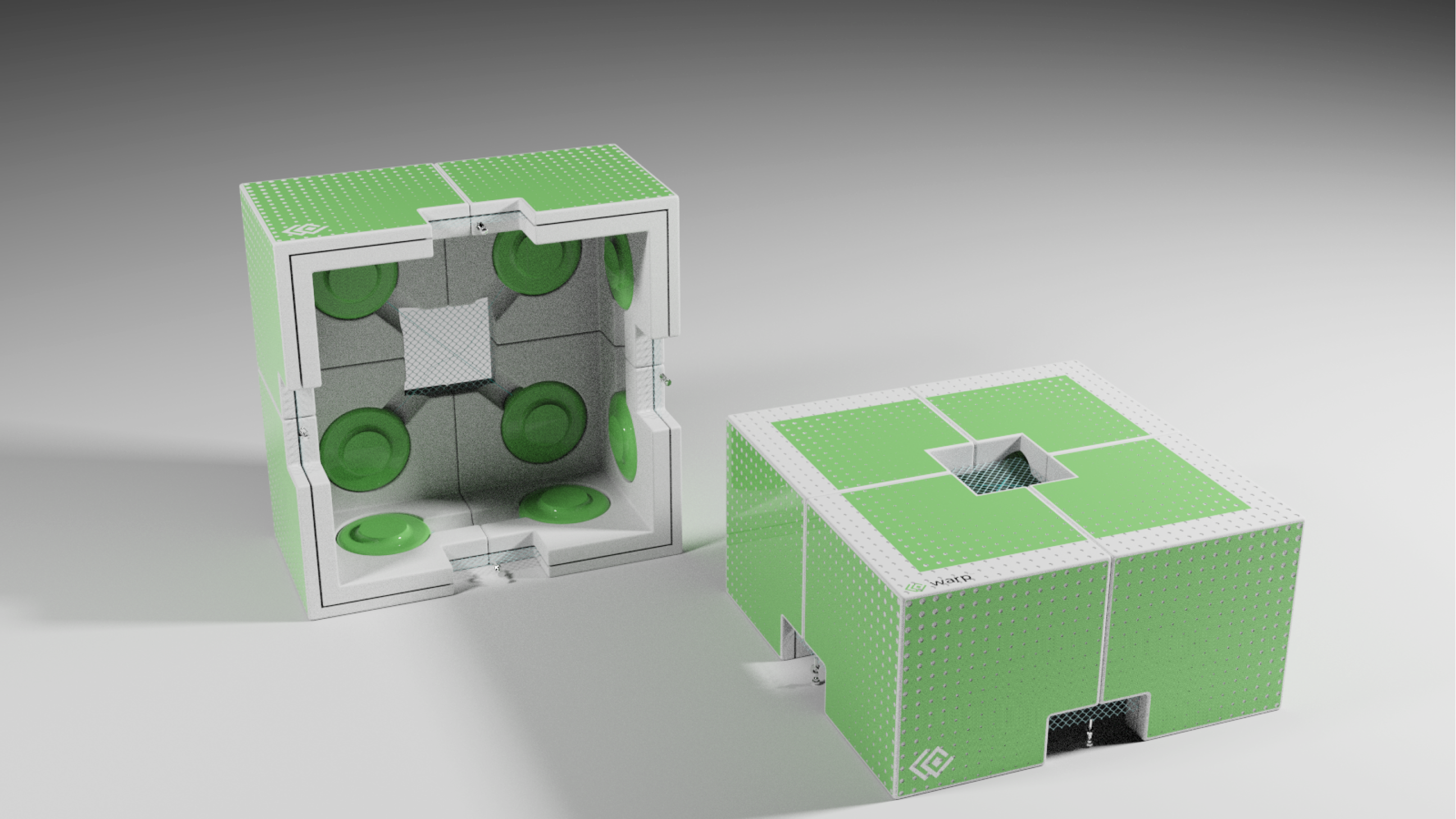

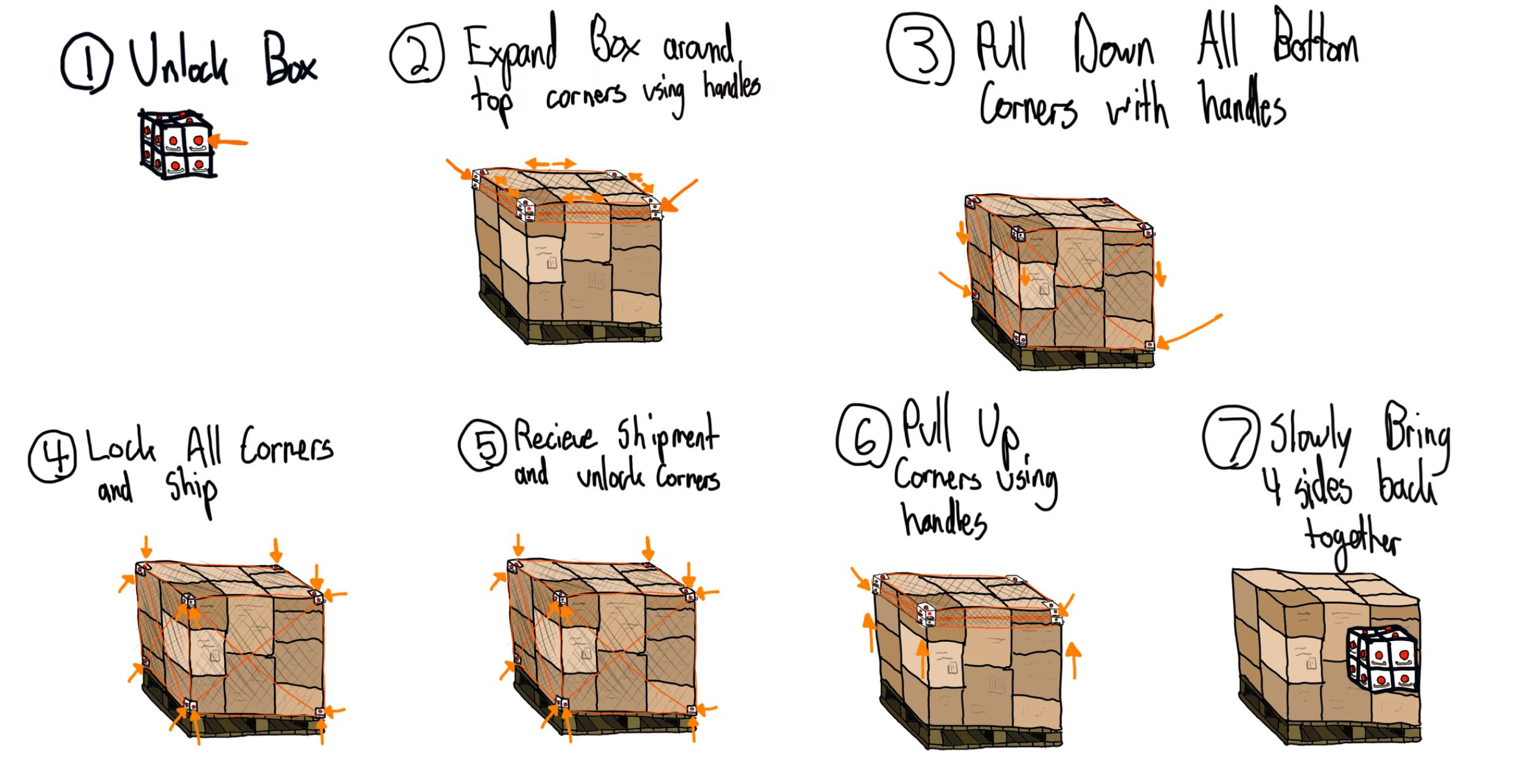

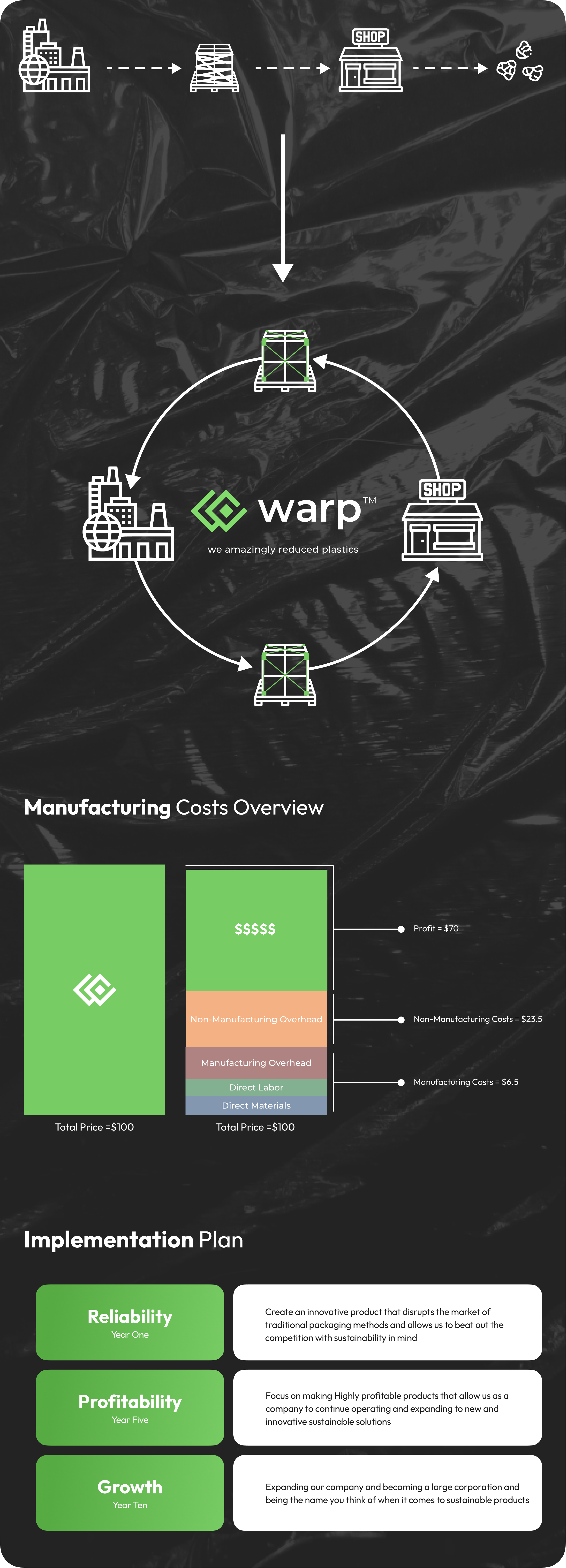

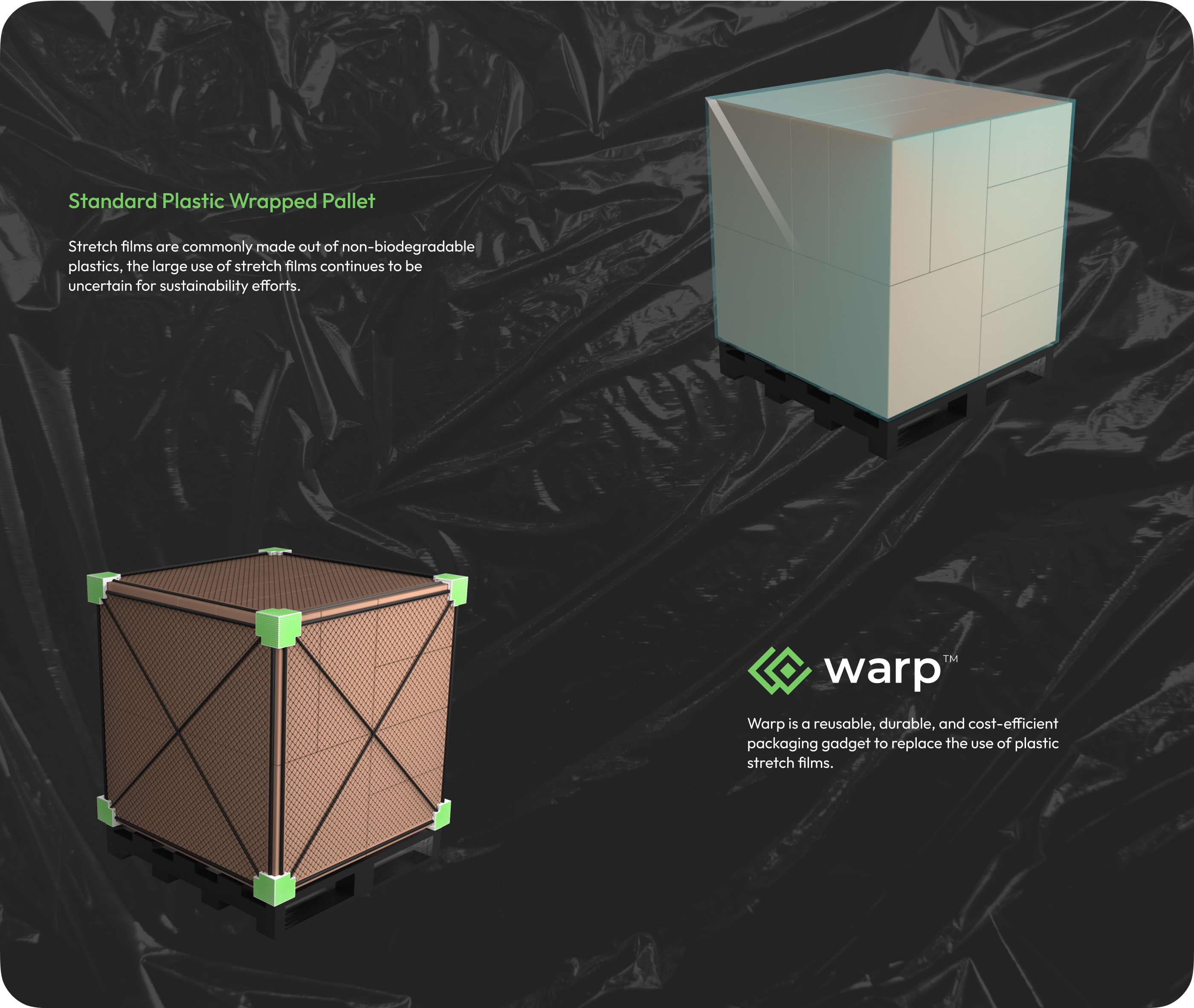

Warp is an innovative B2B solution designed to replace the traditional stretch film from shipping between grocery stores and suppliers which is commonly made out of non-biodegradable plastics. Warp is a reusable, durable, and cost-efficient packaging gadget that is effective in guarding merchandise against environmental damage and at the same time keeping them stable from shipping, where it is created from recycled materials, such as old fishing nets and polyethylene terephthalate (PET), a recycled plastics that made to be remade.